Commonly used in:

-

Hotel

-

Industrial

-

Institutional

-

Office

-

Retail

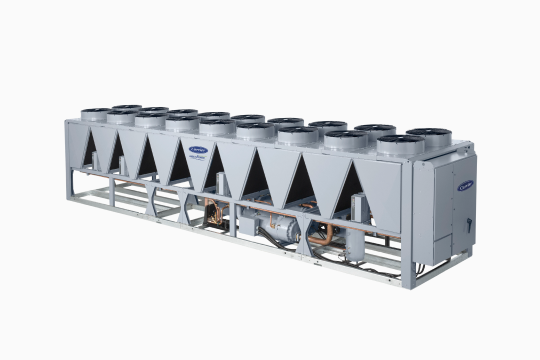

Chiller

Carrier Aquaedge® 19XR Chiller

The AquaEdge® 19XR/XRV centrifugal chillers achieve energy efficiency levels using proven technology designed specifically for chlorine-free refrigerant. This combination ensures the most cost-effective, reliable solution for today’s comfort cooling and process cooling applications.

- HFC-134A or HFC/HFO-513A refrigerant

- Semi-hermetic motors

- ASME heat exchangers and VFD option

- PIC6 controls

Features & Specifications

You are viewing the product features & specifications for the Carrier AquaEdge® 19XR Chiller

Performance Features

- IPLV to 0.31 (19XRV)

- Chlorine-free HFC-134a or R-513A refrigerant

- Semi-hermetic compressor motor

- Low energy consumption during part load and full load operation

- Aerodynamically contoured impeller

- Multilingual display

- Compatible with Carrier Comfort Network® (CCN) communication link

- BACnet IP or MS/TP native compatibility

- Economized two stage compressor (19XR two-stage units)

Reliability Features

- ASME constructed heat exchangers

- Single-stage 200-550 tons (703 to 1,934 kW) or two-stage 600-3400 tons (2110 to 11957 kW) positive pressure design

- Low voltage control circuits

- Semi-hermetically sealed compressor, motor, and transmission

- Automated controls may be tested before start-up

- Refrigerant-cooled or air-cooled unit-mounted variable frequency drive (19XRV)

Maintenance Features

- Password protected extensive service menu with built-in diagnostic capabilities, troubleshooting, and corrective action recommendations for preset alarms

- Alarm and alert files maintain the last 25 time and date stamped messages in memory

- Configuration data backup with non-volatile memory

- Thermistor-type temperature sensor with quick connects in each water nozzle

- Refrigerant isolation valves for in-chiller refrigerant storage (factory-installed option)

- Unit-mounted pumpout unit for storing refrigerant inside the chiller during servicing (factory-installed option)

- Service contract available

Installation Features

- Low voltage control circuits

- Refrigerant-cooled or air-cooled unit-mounted VFD

- Semi-hermetically sealed compressor, motor, and transmission

- Automated controls test on start-up

Factory-Installed Options

- Enhanced tubing, .028 or .035 in. (0.711 or 0.889 mm):

- Internally/externally enhanced copper tubing - evaporator/condenser

- Internally/externally enhanced cupronickel tubing - condenser

- Smooth bore/externally enhanced copper tubing - evaporator/condenser

- Smooth bore/externally enhanced cupronickel tubing - condenser

- Titanium condenser tubes, .025 or .028 in. (0.635 or 0.711 mm):

- Internally enhanced tubes

- Marine waterboxes

- 150 psig (1034 kPa) waterbox

- 300 psig (2068 kPa) waterbox, ASME certified

- Marine bolt-on waterboxes for condenser, 150 psig (1034 kPa) with titanium clad tubesheets (available on condenser frame sizes 2 to 8 and A to D)

- Nozzle-in-head waterbox, 300 psig (2068 kPa)

- Flanged evaporator and/or condenser waterbox nozzles

- Waterbox hinges

- Unit-mounted, low-voltage wye-delta or solid-state starters (Heat exchanger frames 1-7 only)

- One, 2, or 3 pass evaporator or condenser waterside construction

- Zinc anodes

- Refrigerant isolation valves

- Shipped factory charged with refrigerant

- Unit-mounted pumpout unit

- Hot gas bypass

- Unit-mounted refrigerant-cooled or air-cooled variable frequency drive

- Thermal insulation (except waterbox covers)

- Customer factory performance testing

- Export crating

- Discharge line sound reduction kit

- Seismic Kit

- Service Contract

Field-Installed Accessories

- LonWorks® Carrier translator

- Sensor package

- Separate storage tank and pumpout unit

- Stand-alone pumpout unit

- Soleplate package

- Spring isolator kit

- Acoustical sound insulation kit

- Freestanding Low Voltage Wye-Delta & Solid Starters

- Freestanding Low Voltage Variable Frequency Drives

- Freestanding Medium Voltage Variable Frequency Drives

| Heat Exchanger Size† | Length with Nozzle-in-Head Waterbox | Width | Height ** | |||||

|---|---|---|---|---|---|---|---|---|

| 2-Pass* | 1 or 3-Pass | |||||||

| ft-in. | mm | ft-in. | mm | ft-in. | mm | ft-in. | mm | |

| 10 to 12 | 4-Nov | 3454 | 11-Nov | 3632 | 5-2 7/8 | 1597 | 6-1 1/4 | 1861 |

| 15 to 17 | 13-7 1/2 | 4153 | 14-2 1/2 | 4331 | 5-2 7/8 | 1597 | 6-1 1/4 | 1861 |

| 20 to 22 | 11-4 3/4 | 3473 | 11-11 3/4 | 3651 | 5-6 7/8 | 1688 | 6-3 1/4 | 1911 |

| 30 to 32 | 13-8 1/4 | 4172 | 14-3 1/4 | 4350 | 5-6 7/16 | 1688 | 6-3 1/4 | 1911 |

| 35 to 37 | 15-4 3/4 | 4693 | 15-11 3/4 | 4870 | 5-6 7/16 | 1688 | 6-3 1/4 | 1911 |

| 40 to 42 | 14-3 1/8 | 4347 | 14-9 | 4496 | 6-3 1/8 | 1908 | 7-0 3/4 | 2153 |

| 45 to 47 | 15-8 5/8 | 4867 | 16-5 1/2 | 5017 | 6-3 1/8 | 1908 | 7-0 3/4 | 2153 |

| 50 to 54, 5K to 5R | 14-4 1/2 | 4382 | 14-10 | 4521 | 6-6 1/2 | 1994 | 1-Jul | 2159 |

| 5A to 5C | 14-4 1/2 | 4382 | 14-10 | 4521 | 6-6 1/2 | 1994 | 1-Jul | 2159 |

| 55 to 59, 5T to 5Z | 16-1 | 4902 | 16-6 1/2 | 5042 | 6-6 1/2 | 1994 | 1-Jul | 2159 |

| 5F to 5H | 16-1 | 4902 | 16-6 1/2 | 5042 | 6-6 1/2 | 1994 | 1-Jul | 2159 |

| 60 to 64, 6K to 6R | 14-5 1/4 | 4401 | 14-11 | 4547 | 6-11 5/8 | 2124 | 7-4 7/8 | 2257 |

| 65 to 69, 6T to 6Z | 16-1 3/4 | 4921 | 16-7 1/2 | 5067 | 6-11 5/8 | 2124 | 7-4 7/8 | 2257 |

| 70 to 74, 7K to 7R | 16-6 1/8 | 5032 | 17-0 1/2 | 5194 | 8-1 1/4 | 2470 | 9-9 1/2 | 2985 |

| 75 to 79, 7T to 7Z | 18-6 1/8 | 5642 | 19-0 1/2 | 5804 | 8-1 1/4 | 2470 | 9-9 1/2 | 2985 |

| 80 to 84, 8K to 8R | 16-9 1/8 | 5109 | 17-3 1/2 | 5271 | 8-10 3/4 | 2711 | 9-11 1/4 | 3029 |

| 85 to 89, 8T to 8Z | 18-9 1/8 | 5718 | 19-3 1/2 | 5880 | 8-10 3/4 | 2711 | 9-11 1/4 | 3029 |

*Assumes all customer connections are on the same end of the chiller.

**Height is for chiller without unit-mounted starter.

†Heat exchangers are rated for typical applications at AHRI Conditions (44°F leaving chilled water and 54 F entering in the evaporator, and 85°';F entering condenser water with 94.3 leaving condenser water in the condenser).

19XR Dimensions – Two-Stage Compressor Frame Sizes 6 & 7 (Dished Head Waterbox)

| Cooler Heat Exchanger Size | Condenser Heat Exchanger Size | A (Length, Dished Head Waterbox) | 19XR B Width | 19XR C Height | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1-Pass | 2-Pass | 3-Pass | ||||||||

| ft-in. | mm | ft-in. | mm | ft-in. | mm | ft-in. | mm | |||

| A4* | A4* | 17-8 | 5385 | 17-6.75 | 5353 | 17-6.75 | 5353 | 10-3.13 | 3127 | See Note 6 |

| A6* | A6* | 19-8 | 5994 | 19-6.75 | 5962 | 19-6.75 | 5962 | 10-3.13 | 3127 | |

| A4* | B4* | 17-8 | 5385 | 17-7.38 | 5369 | 17-7.38 | 5369 | 10-8.5 | 3264 | |

| A6* | B6* | 19-8 | 5994 | 19-7.38 | 5978 | 19-7.38 | 5978 | 10-8.5 | 3264 | |

| B6* | C6* | 20-0 | 6096 | 19-11.18 | 6074 | 19-9 | 6120 | 12-0.63 | 3674 | |

| B8* | C8* | 22-0 | 6096 | 21-1.18 | 6684 | 21-9 | 6629 | 12-5.5 | 3797 | |

| C6* | C6* | 20-4.25 | 6204 | 19-11.18 | 6074 | 19-11.75 | 6090 | 12-5.5 | 3797 | |

| C6* | D6* | 20-4.25 | 6204 | 20-0 | 6096 | 20-0.5 | 6109 | 13-2 | 4013 | |

| C8* | D8* | 20 | 6096 | 21-11.125 | 6684 | 21-9 | 6629 | 13-2 | 4013 | |

*Assumes both cooler and condenser nozzles on same end of chiller.

Note 6. 19XR heights can vary depending on the configuration. Check 19XR certified drawings for height information.

The AquaEdge® 19XR/XRV centrifugal chillers achieve energy efficiency levels using proven technology designed specifically for chlorine-free refrigerant. This combination ensures the most cost-effective, reliable solution for today's comfort cooling and process cooling applications.

Learn from our Client Testimonials

-

Alstra (formerly known as Concepcion-Building and Industrial Solution) has been a valued partner at Park Terraces. I have personally witnessed the way they work and I am very happy with the products and the level of service they provide.

Cherryl Uy

Area Head - Central Projects

Project Development Group

Ayala Land Premier

-

One vital aspects in residential building operations is to have air conditioned lobbies that exceed cooling expectations of our residents. Carrier provided us with efficient, reliable and low operating costs air conditioners that made us confident in providing cooling comfort which met our residents need.

Jovan Barargo

Building Manager

Edades Tower & Proscenium at Rockwell

-

Partnering with Alstra, formerly Concepcion-Building & Industrial Solutions, is a strategic move that has helped us not only in managing better the cooling requirement of our branches but in keeping our expenses low as well. The 3 & 5 TR inverter, floor-mounted & ceiling cassette units are key to us providing an office conducive to do business transactions; keeping both our clients & employees happy.

Ma. Kathleen S. Aquino

Team Head

Supply Chain Management Division

Bank of the Philippine Islands

-

We have no issue with the timeliness in terms of deliverables, equipment supply and installation, which was duly met as committed. Their on-site team executed quality workmanship.

Alvin Olanday

Project Director

Makati Development Corporation

-

The indoor units, which range from cassettes, wall hung and ceiling types, were well designed and very well installed. We are very happy with the supply work of Alstra (formerly known as Concepcion-Building and Industrial Solution) and look forward to a continued business relationship as partners for the DLSZ Air Conditioning System.

Mr. Charles Rapaport

Project Head

Dela Salle Santiago Zobel-

Vermosa Campus

Support 24/7

- Ready to cater to your every need

- Ask a question

Tried. Tested. Trusted

- Our rigorous tests and original parts ensure excellent quality

Carrier Authorized

- Our skilled technicians undergo extensive training so your unit is in good hands

- Visit Customer Care

Tell us about your Carrier Aquaedge® 19XR Chiller

How would you rate this product?