Project Summary

-

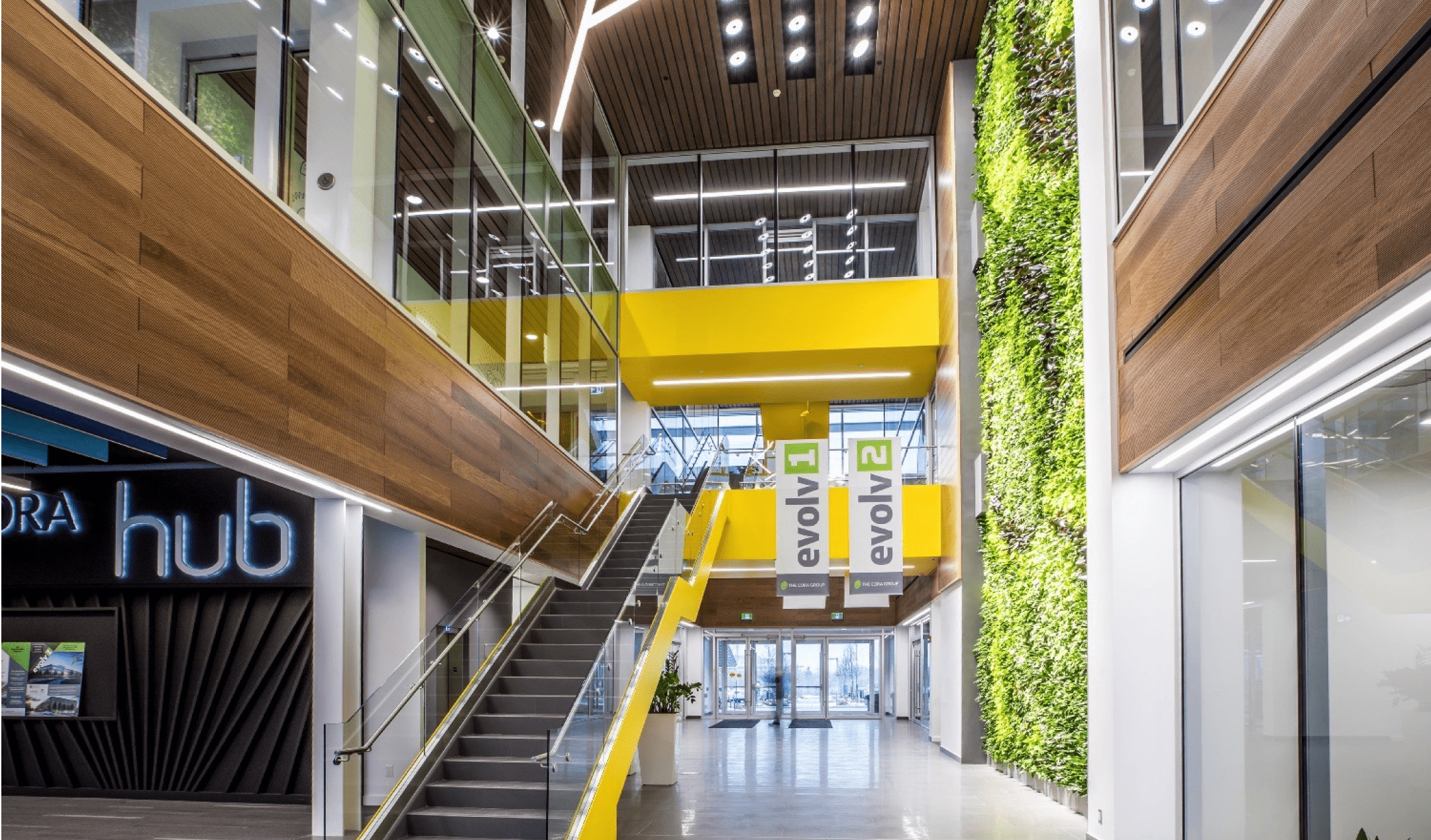

Location

Waterloo, ON Canada

-

Project Type

Building automation and controls

-

Building Size

104,000ft2

-

Facility Usage

Multi-Tenant Office Building

-

Controls

Carrier i-Vu Pro 7.0 BAS

-

Installation Date

2018