At Carrier, we understand that your equipment is your investment. When your equipment breaks down or wears out, aside from the direct expenses of having to repair or replace parts, you may also face a whole slew of related problems. Unnecessary costs such as higher electricity bills due to HVAC inefficiency; reduced productivity as your staff deals with an uncomfortable indoor climate; and production losses caused by the shutdown of your HVAC equipment--these are just some of the many situations that can negatively impact your business.

By partnering with us and availing yourself of our aircon repair services, preventive maintenance services, and more, we hope to help:

Our Service Solutions team is composed of multiple subunits specialized to handle each step in our process with the highest level of expertise.

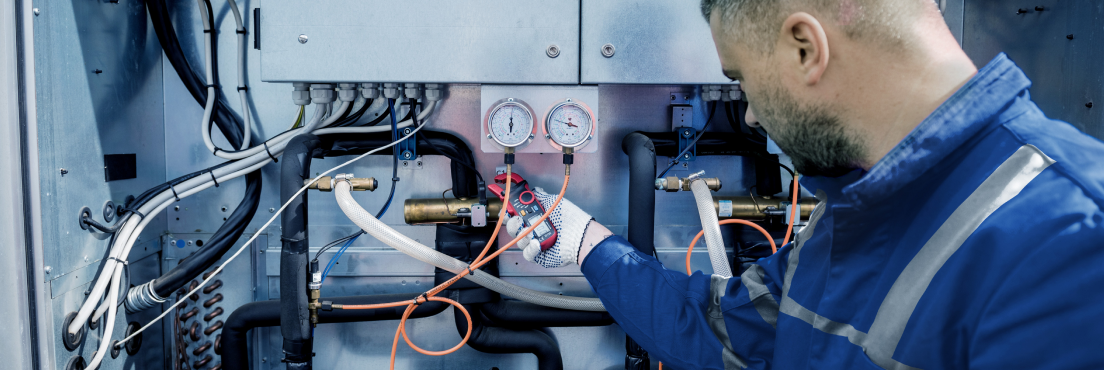

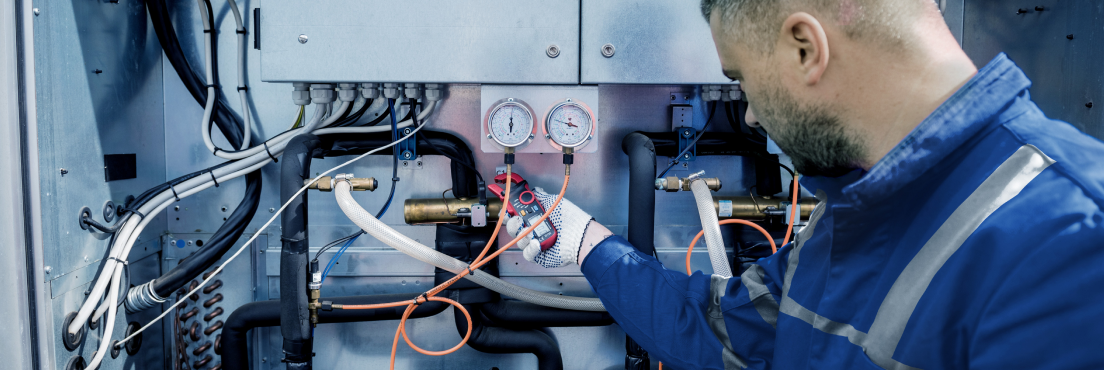

Our experienced and certified technicians regularly undergo training on servicing and troubleshooting equipment, supplying the most up-to-date information on recent changes or updates to the technology. This ensures that they can perform air conditioning repair services and preventive maintenance services on all Carrier products.

For complex jobs, we employ dedicated project management teams to consolidate the list of tasks, oversee their prompt execution, and essentially make sure such jobs are running smoothly and being performed according to industry standards.

Lastly, our contact center allows us to accommodate service requests and requirements. We’ve also built in a feature of automatic escalation to higher management if requests are left unattended or unresolved so they are addressed as soon as possible.

Our technical subunits use the latest diagnostic tools to make accurate assessments and analyses of your HVAC product or system, ranging from simple to complex, and diagnose exactly what it requires for repair, upgrade, maintenance, or optimization.

We also only supply and use genuine and factory-authorized parts so you are guaranteed the best possible performance for your specific Carrier aircon or HVAC system.

We offer a comprehensive Operations and Maintenance Program in order to maximize the life of your equipment and ensure its peak performance over its lifespan. By availing yourself of this HVAC service, you can reduce equipment downtime, minimize the need for repairs, improve safety, and reduce unnecessary costs.

When you work with us, these periodic services can be made available to you:

Monthly Chiller Maintenance

As an OEM factory-certified maintenance provider, we take care to ensure that all your equipment is diligently inspected and operating properly, and that all OEM maintenance procedures are being followed.

Annual Shutdown Chiller Maintenance

This includes changing your oil and oil filter after the first year of service (when the compressor bearing break-in period occurs) and a yearly oil analysis afterwards.

Regular inspection

This encompasses other equipment including the AHU (Air Handling Unit), FCU (Fan Coil Unit), Pumps, and Cooling Towers.

Chiller Plant Operations and Maintenance

This service is recommended for customers who demand the highest equipment reliability and uptime alongside with fiscal certainty. It provides protection with allocations for the repair or replacement of failed components of your chiller.

Preventive Maintenance Services

During the course of our regular maintenance, we can also provide Predictive Maintenance Services. These procedures utilize the latest diagnostic and analysis tools to ensure that your entire HVAC system remains in the best shape and performs at optimal levels. Our Predictive Maintenance Services include:

1. Thermo Graphic Analysis

2. Vibration Analysis

3. Insulation Test

4. Fluid Analysis

5. Cooler Analysis

6. Control Panels

7. Pump Motors (Pump Heads section)

8. Pump Motors (general)

9. Oil Analysis

10. Boroscope

Other Benefits

By enrolling in our Operations and Maintenance Program, you also have the option of enrolling in CIC’s troubleshooting services. These include:

Free troubleshooting/emergency calls

Special parts pricing and special discounts

Special limited access to the Carrier Service

Management website

Support from the source factory and the global

Carrier service

By availing yourself of our services, you also gain easy access to securing fast moving spare parts to increase equipment reliability, thereby cutting down the waiting time of parts deliveries. You could also secure cheaper costs on parts by ordering early on. Easy access to fast moving parts are available for the following:

Electrical components of chillers, e.g. sensors, transducers, boards, and relays

Consumable chiller parts, e.g. oil filter, filter drier cores, refrigerant, compressor oils, etc.

If you currently work with non-Carrier affiliated service and/or maintenance groups, they may suggest using “copy” or “duplicate” parts to repair your Carrier products or systems. We cannot attest to the reliability of these parts and your results may vary. We, at Carrier, only use and offer genuine parts from the source factory so you receive the intended, authentic Carrier experience.

Our retrofitting services can extend the lifespan of your existing equipment, allowing you the option to upgrade what you already have instead of having to replace it entirely. For more information regarding our retrofit services, click here.